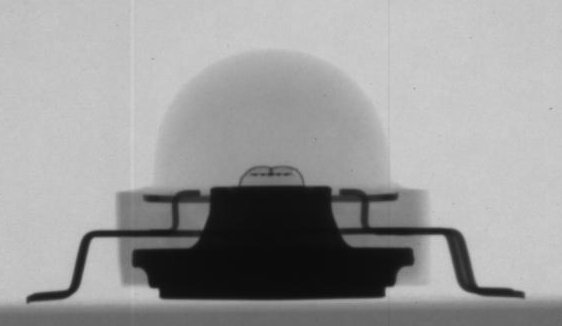

X-Ray Imaging

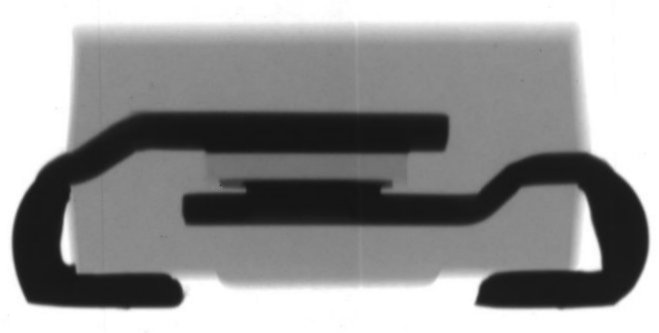

Real-time x-ray imaging is done in transmission and the image can be captured using film or an x-ray imaging system. The sample may be rotated to allow various perspectives, within the limitations of the sample size and geometry.

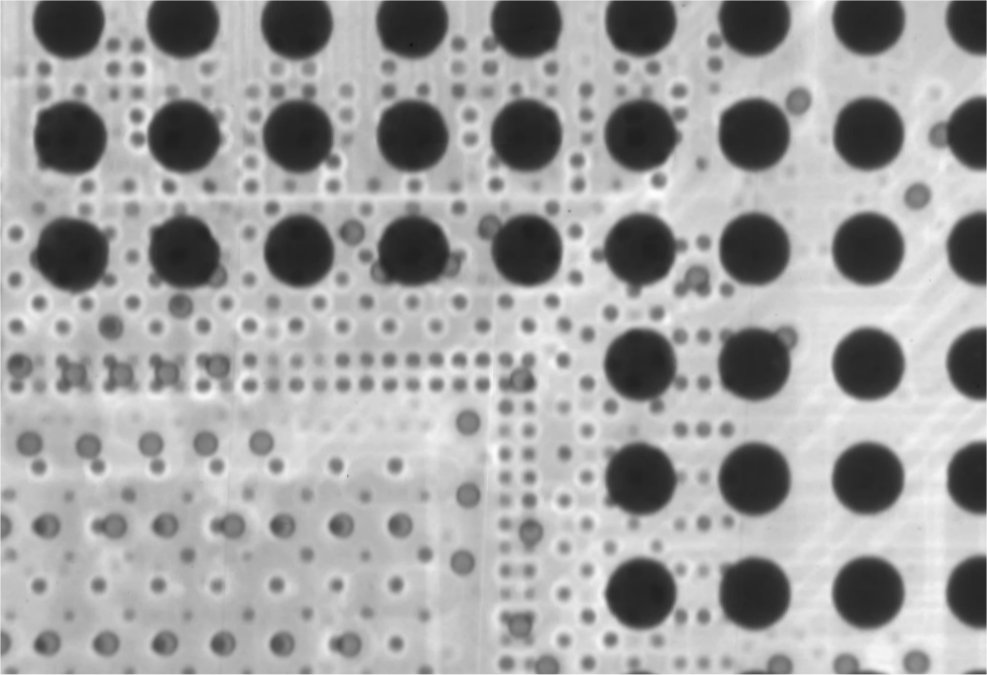

X-ray imaging is a quick, non-destructive analysis technique to look at solder joint quality and the large scale structure of devices.

Typical applications

- Failure analysis

- Reverse engineering

- Reliability analysis

- Forensic analysis

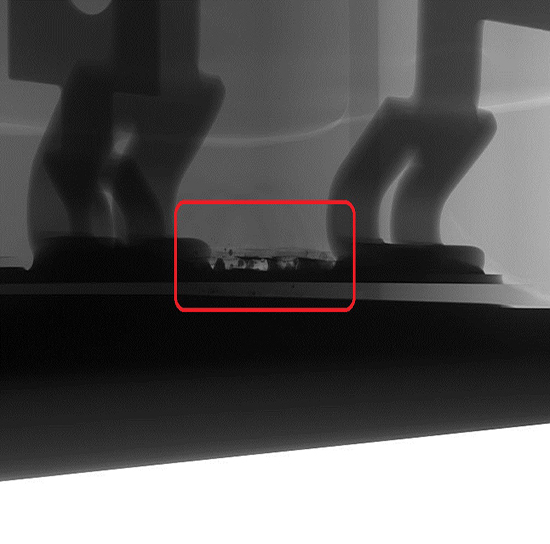

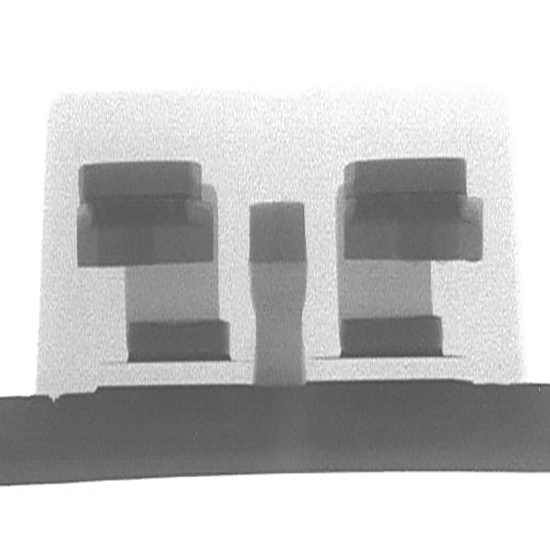

Detection of:

- Defects and voids in BGA balls, QFNs

- Wire bonding defects

- Metallization burnout

- Voids in through hole pins.

Evaluation of:

- Die attach integrity

- Solder bump quality

Techniques

- 100kV x-ray imaging system upgraded to 1024×1024 pixel CMOS sensor

- X-ray on film for military applications

- 3D x-ray available by special request

If defects are detected, recommendations are made for further tests or analyses.